We bring innovative solutions in design and construction of ecological spaces for better living.

Request exclusive consultation with Ecofab expert

We design and build all types of ecological living spaces

Ecofab design projects

House type: Single storey house with flat roof

Total project size: 100,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Two storey house with flat roof

Total project size: 117,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Single storey house with flat roof

Total project size: 115,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Two storey house with flat roof

Total project size: 95,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Two storey house with flat roof

Total project size: 144,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Single storey house with flat roof

Total project size: 150,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Single storey house with flat roof

Total project size: 130,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Single storey house with flat roof

Total project size: 150,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Two storey house with flat roof

Total project size: 111,6 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Single storey house with flat roof

Total project size: 150,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Single storey house with flat roof

Total project size: 148,0 m2

Approx. construction time: 90 days

Project price: from 1 600 € per m2

House type: Single storey house with gable roof

Total project size: 41,0 m2

Approx. construction time: 60 days

Project price: from 1 600 € per m2

House type: Single storey house with gable roof

Total project size: 45,0 m2

Approx. construction time: 60 days

Project price: from 1 600 € per m2

House type: Single storey house with gable roof

Total project size: 68,0 m2

Approx. construction time: 60 days

Project price: from 1 600 € per m2

House type: Single storey house with gable roof

Total project size: 141,0 m2

Approx. construction time: 60 days

Project price: from 1 600 € per m2

House type: Single storey house with gable roof

Total project size: 62,0 m2

Approx. construction time: 60 days

Project price: from 1 600 € per m2

House type: Single storey house with gable roof

Total project size: 130,0 m2

Approx. construction time: 60 days

Project price: from 1 600 € per m2

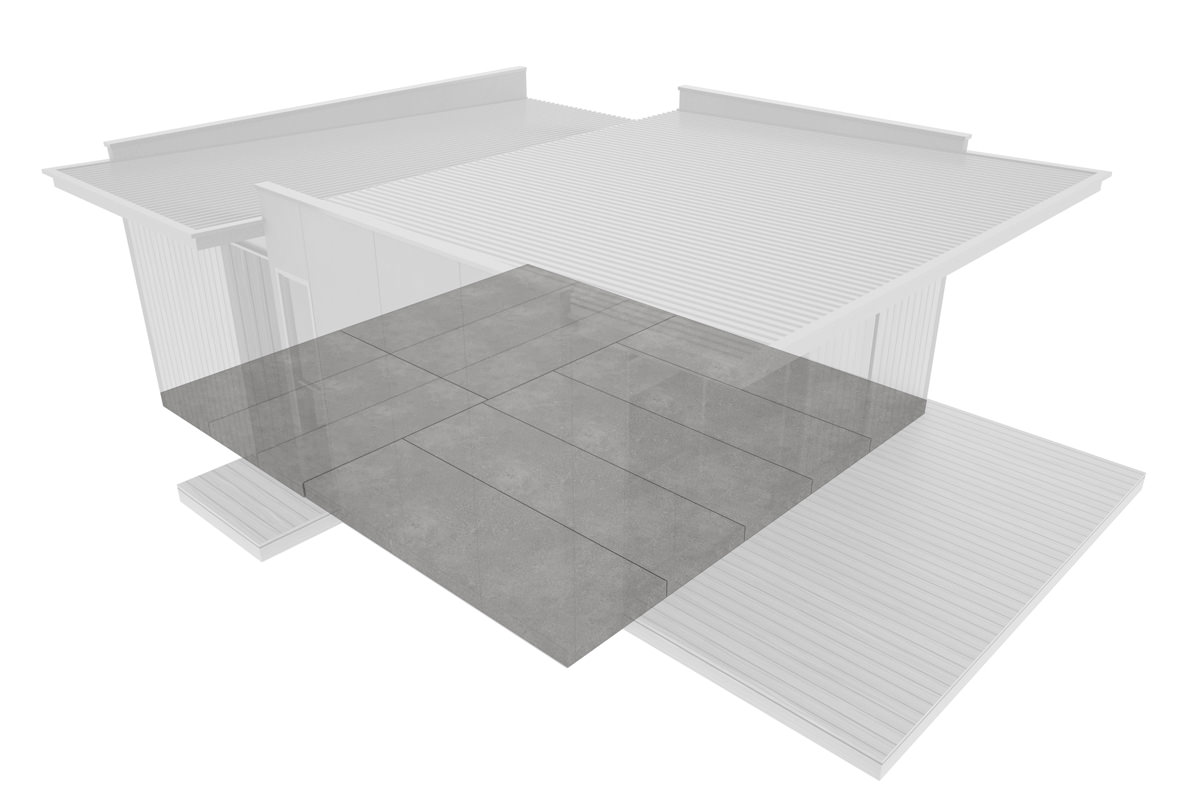

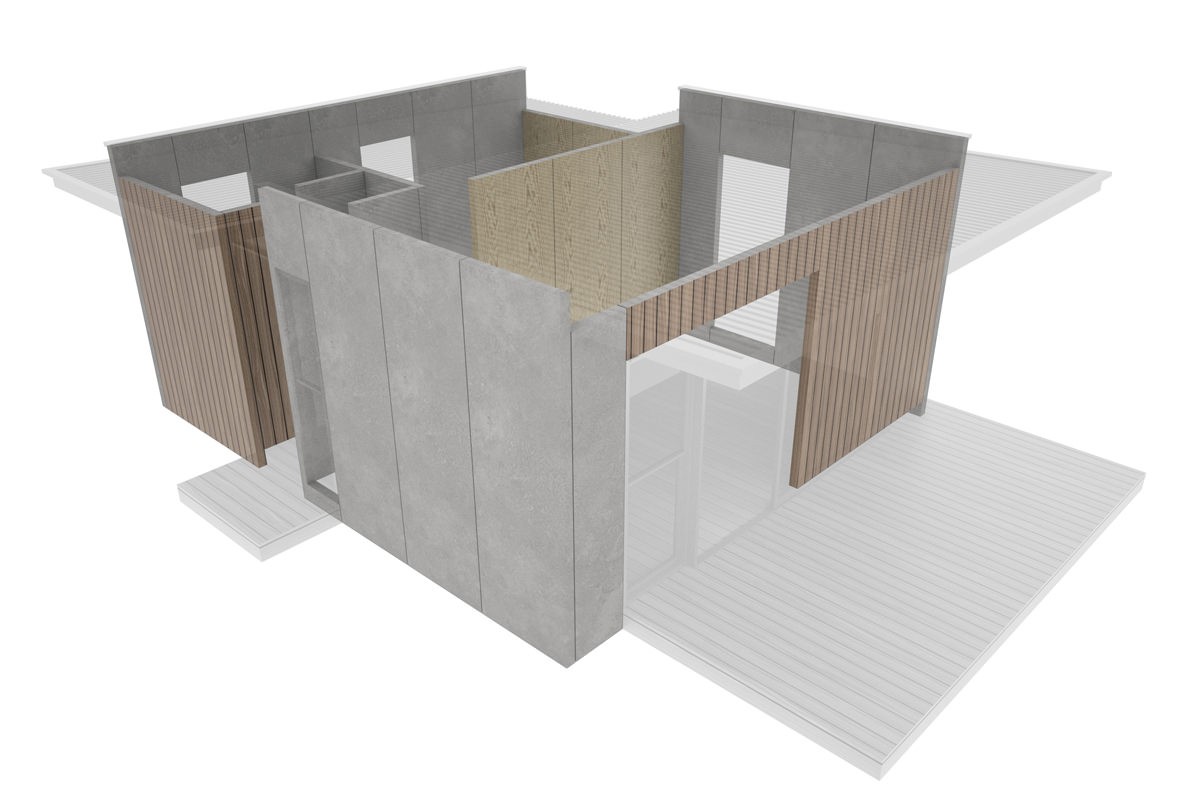

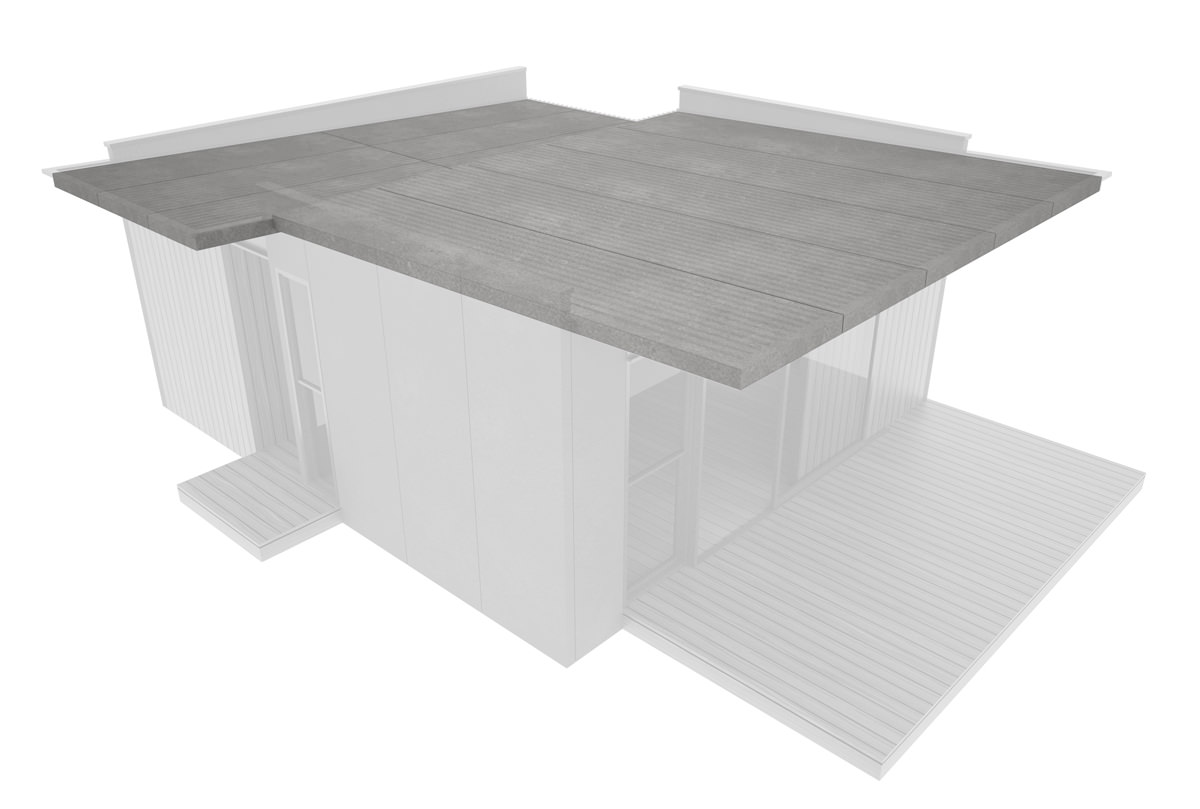

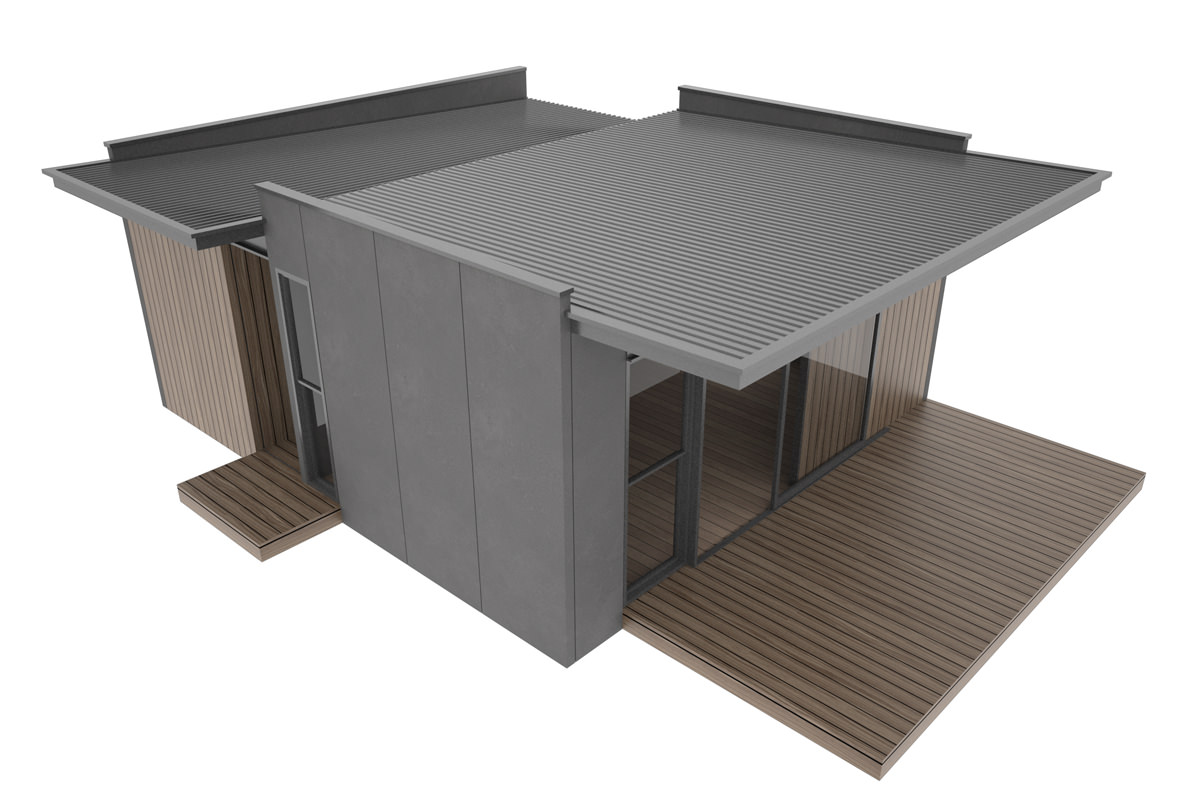

House type: Single storey garden cabin with flat roof

Total project size: 41,0 m2

Approx. construction time: 30 days

Project price: from 1 600 € per m2

House type: Single storey garden cabin with flat roof

Total project size: 35,0 m2

Approx. construction time: 30 days

Project price: from 1 600 € per m2

House type: Single storey garden cabin with flat roof

Total project size: 27,0 m2

Approx. construction time: 30 days

Project price: from 1 600 € per m2

House type: Single storey garden cabin with flat roof

Total project size: 21,0 m2

Approx. construction time: 30 days

Project price: from 1 600 € per m2

House type: Single storey garden cabin with flat roof

Total project size: 39,0 m2

Approx. construction time: 30 days

Project price: from 1 600 € per m2

House type: Single storey office space with flat roof

Total project size: 41,0 m2

Approx. construction time: 30 days

Project price: from 1 600 € per m2

House type: Single storey office space with flat roof

Total project size: 35,0 m2

Approx. construction time: 30 days

Project price: from 1 600 € per m2

House type: Single storey office space with flat roof

Total project size: 25,0 m2

Approx. construction time: 30 days

Project price: from 1 600 € per m2

We are creating access to a new way of future living

Low-cost

The low weight of Ecofab building technologies reduces the cost of building a foundation and building a house. And house's energy efficiency will cause to up to 100% reduction on the bills.

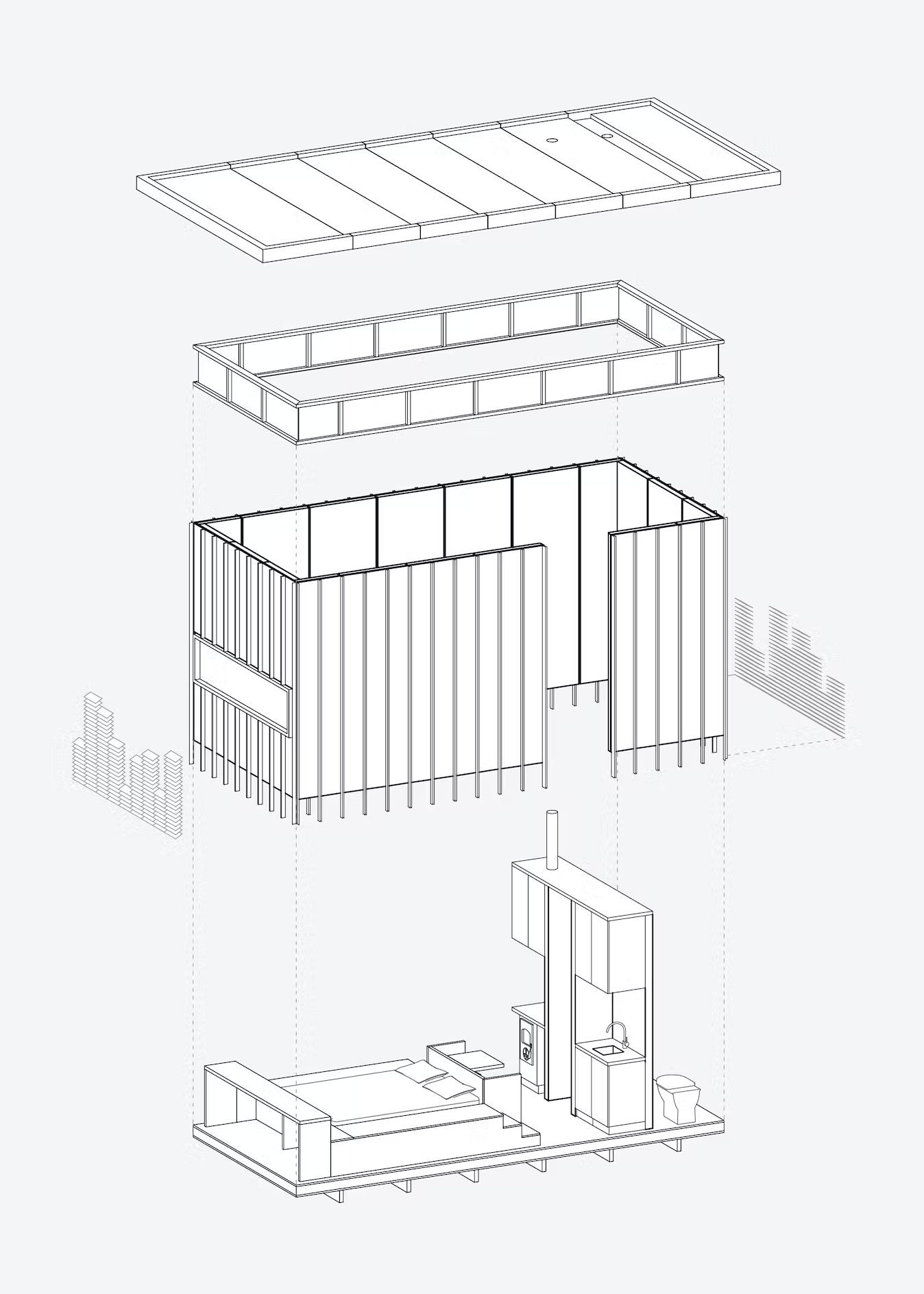

Construction speed

All materials are made in fabric, and the construction process is similar of the block constructor. Ecofab house can be built in 1 week!

Strong and durable

Houses made of Ecofab materials do not collapse even with an earthquake of 7 on the Richter scale. Have strong fire resistance and also demonstrated a great capacity to withstand the most devastating winds, such as Category 5 hurricanes.

Long-lasting

Modern houses made of high-quality and innovative Ecofab building technology are designed to operate up to 100 years.

Environmental-friendly

High-quality materials that are used in the construction are absolutely safe for health and respect the environment.

Energy efficient

The cost of heating a Ecofab house is up to five times lower than for heating a house made of brick, foam concrete or timber. And this are a serious savings year after year!

Stunning designs

We offer design projects of houses, the quality of which has been tested in practice. You will receive the convenience and comfort of already thought-out solutions optimized for Ecofab technology.

Smart technologies

Control your Ecofab house with intelligent technology. Connect your security, lighting, blinds, heating, aircon, music and TV – with our Smart Home Automation system. Be eco. Be smart.

Request exclusive consultation with Ecofab expert

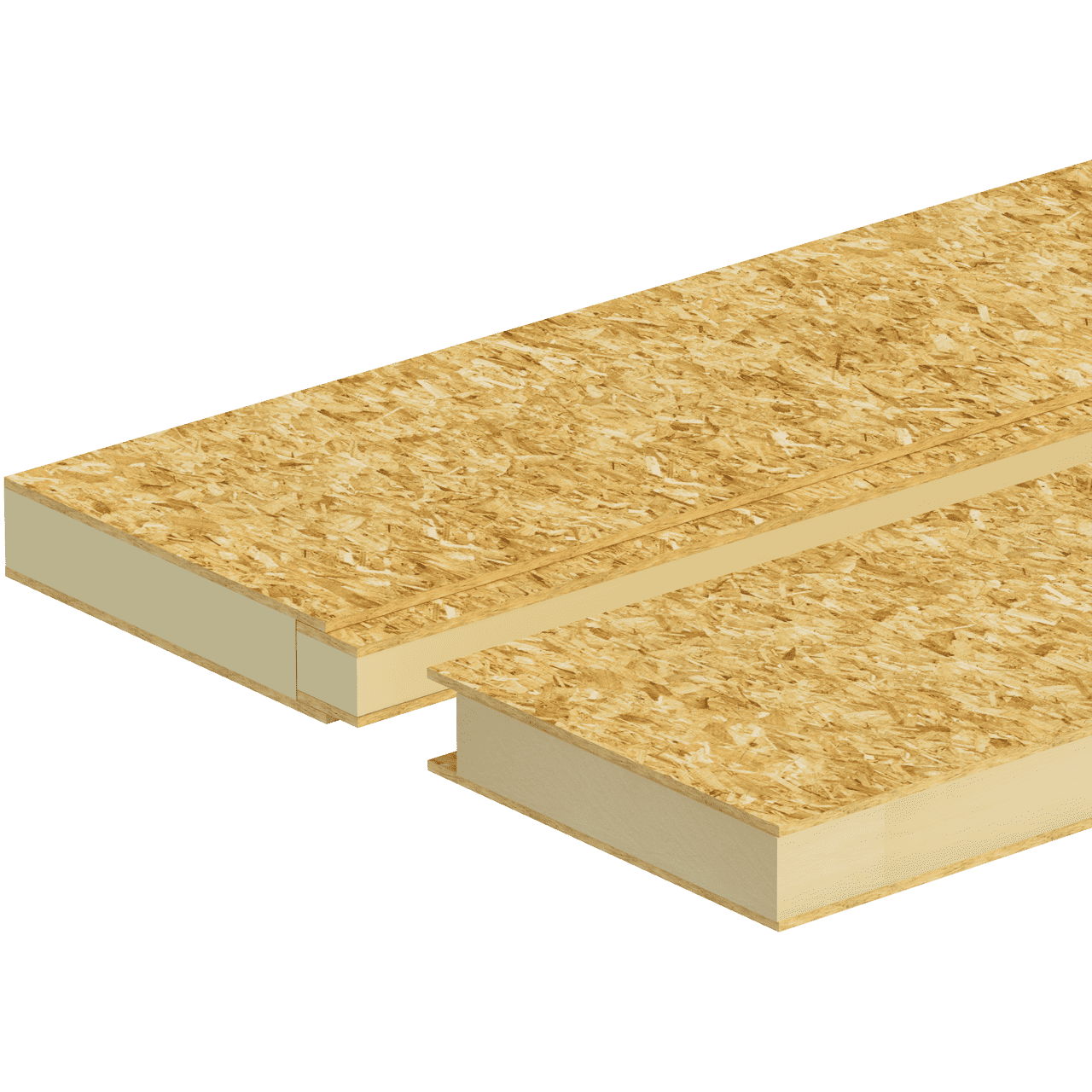

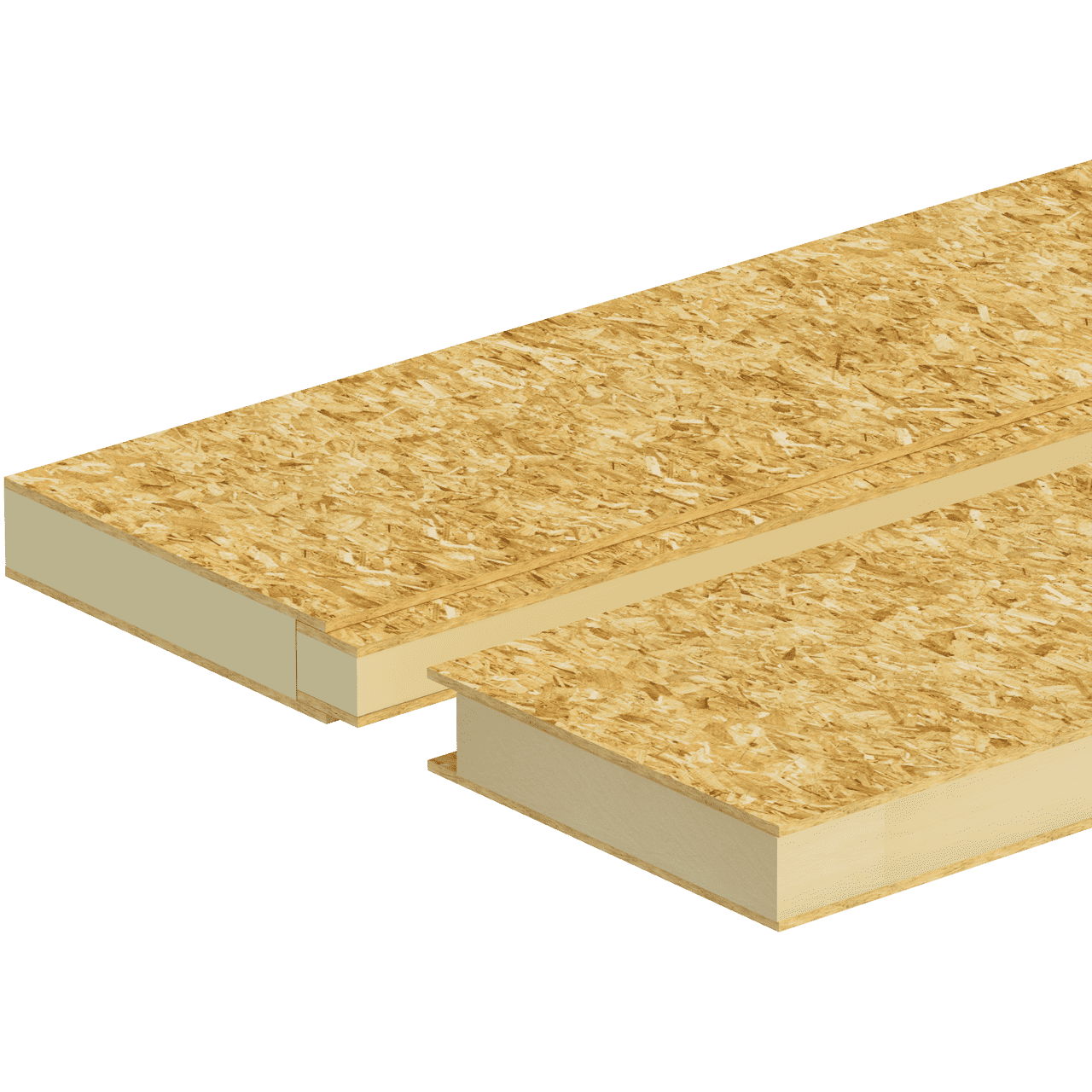

About Ecofab building technologies

Fire resistance

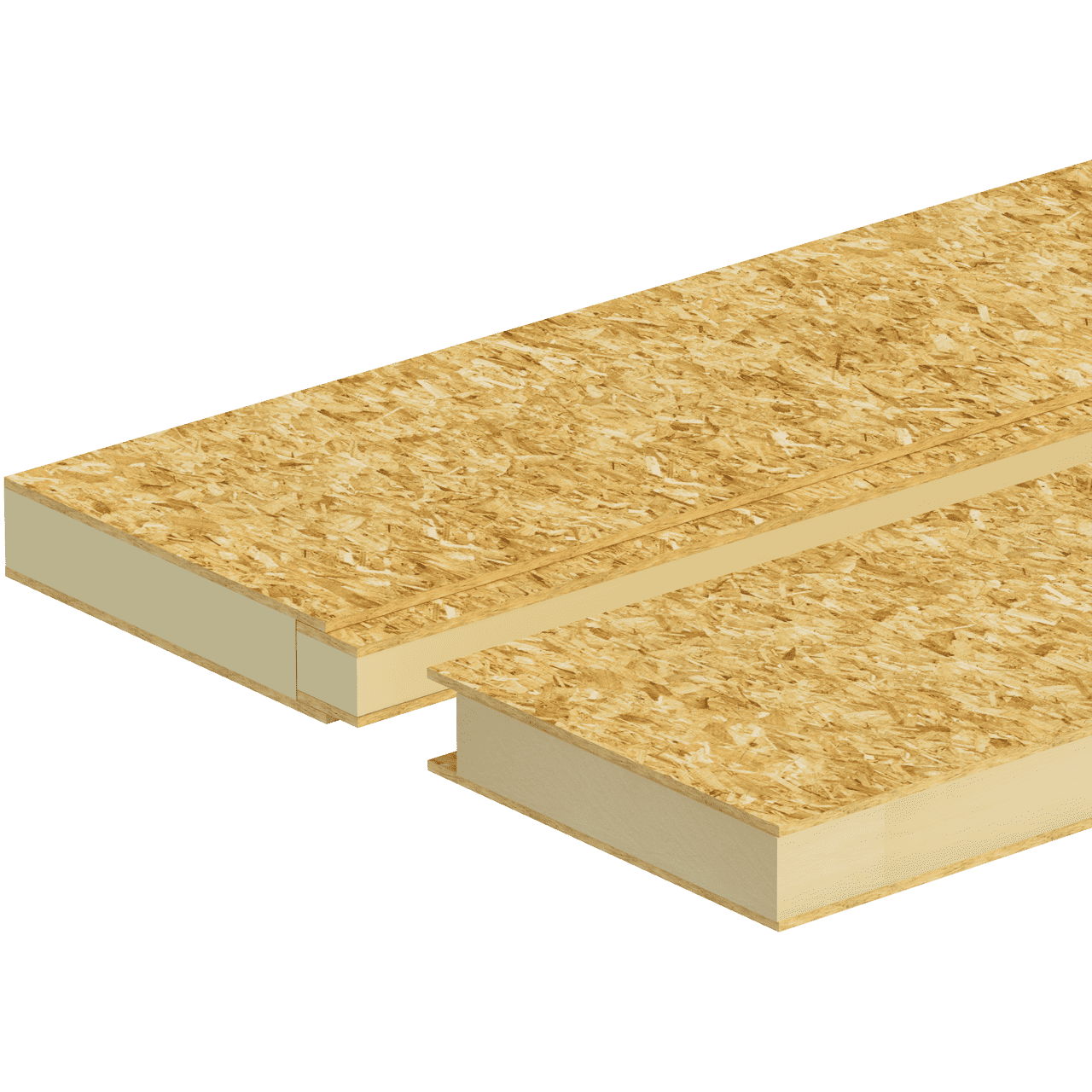

Magnesium Oxide panels are fire-resistantand have some of the highest fire-safety classifications as calculated by industry regulators. This is especially significant when using MgO Structural Insulated Panels (SIPs). Generally used on a building’s exterior, SIPs are comprised of an insulating foam core inserted between MgO sheathing to provide superior insulation. But the double-sided layers of fire-resistant material also provide a very low flame spread rating (the classification of a material’s surface burning characteristics).

Storm resistance

MgO products are more impact resistant than legacy building materials, meaning high-speed collisions from debris driven by storm high winds can be better endured by structures incorporating MgO Structural Insulated Panels (SIPs) and other exterior MgO building materials. Coupled with fire resistance (lightning strikes) and the ability to withstand water damage (flooding).

Water resistance

MgO panels do not rapidly deteriorate when immersed in water over a short period — as happens in floods and extreme rainfall events — and can maintain structural stability even under the force of minor bending. High-performance Magnesium Oxide building materials do not warp, swell, or delaminate. They are not fully waterproof but compared to most wood and all gypsum drywall products they are far more resilient when facing temporary water inundation.

Insect resistance

One of the most crucial benefits of Magnesium Oxide panels, especially when replacing plywood and other wood products, is that bugs are not attracted to MgO. Since MgO PANELS contain no organic materials, termites, carpenter ants, wood borers, powder post beetles, and every other wood-munching bug won’t make a meal out of high-performance building panels made with MgO.

Earthquake resistance

MgO PANELS based panels have dimensional stability that make these panels a impotant addition to earthquake-proof building design. Since MgO products are molded using coordinated chemical reactions, they are extremely solid when cured, creating a hardened material that is enduringly stable. The Great Wall of China and many Roman buildings originally built with MgO cement are still around for a reason.

Eco-friendly

The energy efficiency of MgO PANELS is a big part of why MgO products are so good for the environment. They are constructed without the use of toxic materials, are completely recyclable, can be disposed of safely without fear of leaching toxins into surrounding groundwater, and their manufacture actually captures carbon dioxide. In fact, significant research into using magnesium oxide as a tool to lessen the buildup of greenhouse gases in the Earth’s atmosphere is currently underway.

Energy efficient

MgO PANELS are highly energy-efficient and therefore contribute positively to the environment by reducing CO2 levels. They also use significantly less energy during the manufacturing process compared to traditional construction methods and have lower embodied energy than traditional construction materials, such as steel, concrete and masonry.

Improved air quality

Building with MgO PANELS allows for better control over indoor air quality because the airtight building envelope limits incoming air to controlled ventilation. Controlled ventilation filters out contaminants and allergens, and also allows for incoming air to controlled ventilation. This will reduce the possibility of mold and dust.

Fire resistance

Contrary to misconceptions, CLT exhibits good fire resistance due to the charring effect. The outer layer burns slowly, providing a natural fire barrier that can potentially contribute to improved safety.

Sustainability

CLT is a champion in sustainability. Being made from wood, a renewable resource, it significantly reduces the carbon footprint associated with construction materials. The production of CLT requires less energy compared to traditional construction materials like concrete or steel, making it a greener choice.

Strength and Durability

Despite its relatively lightweight nature, CLT boasts impressive strength and durability. The cross-laminated layers enhance its load-bearing capacity, making it suitable for a variety of applications, including mid-rise and even high-rise buildings.

Speedy Construction

CLT panels are prefabricated off-site, which results in faster construction times. This not only reduces the overall construction schedule but also minimizes disruption to the surrounding environment.

Design Flexibility

Architects and designers love working with CLT due to its flexibility in CLT design. CLT panels can be customized to various shapes and sizes, enabling the creation of unique and aesthetically pleasing structures.

Improved Insulation

CLT’s layered structure inherently offers better insulation than traditional materials. This can lead to improved energy efficiency in buildings, reducing heating and cooling costs.

Lightweight Construction

CLT’s lightweight nature makes it suitable for retrofitting and additions to existing structures, minimizing the need for extensive foundational changes.

Reduced Noise Transmission

The dense composition of CLT panels helps reduce noise transmission between rooms and floors, contributing to enhanced acoustic comfort.

Autoclaved Aerated Concrete (AAC) block is a low-maintenance precast building material with excellent thermal insulation and durability. The heat-insulating properties of AAC blocks keep the building cooler and prevent outside heat from entering, resulting in significant savings on air conditioning costs. AAC blocks also guarantee savings in foundation load, structural steel consumption, and mortar consumption.

Easy & Faster Workability

AAC blocks are about half the weight and ten times the size of traditional bricks. This one-of-a-kind property allows for simple installation and provides the desired flexibility, making adjustments, cutting, shaping, and so on a breeze. AAC blocks have fewer joints and consistent dimensions, making them easier to lay and the construction process faster. Finally, lightweight blocks are easy to transport, which helps to reduce overall logistics and shipping costs when compared to traditional brick transportation costs.

Sustainable And Pocket-Friendly

AAC blocks are produced with a minimum amount of waste using natural, non-toxic raw materials. Some of the waste or offcuts produced can be recycled or used to make aggregates. Its use of non-biodegradable materials makes the building more durable and steady, preventing rot and mould. Furthermore, because AAC blocks are lightweight, energy-efficient, and simple to install, they reduce labour costs.

Disaster Resistant

Self-weight and gravity are usually the two vertical forces that a building is designed to handle. Earthquakes, for example, cause horizontal forces. As a result of the manufacturing process, AAC blocks become extremely strong, resulting in a durable finished structure. In comparison to conventional bricks, AAC bricks can handle higher seismic loads.

Thermal Insulation And Energy Conservation

By foaming the concrete with hydrogen, the material provides excellent heat insulation, allowing temperatures to be warm in winter and cool in summer. Thus, it can reduce your air-conditioning costs by about 25%. Due to their energy-efficient production, AAC blocks are energy-efficient throughout their lifetimes.

Soundproof

Because AAC blocks are lightweight and porous, they reduce sound significantly. It is for these reasons that AAC blocks are widely used in the construction of studios, hospitals, hotels, etc.

Fire Resistance

Comparatively to other building materials, AAC blocks are noncombustible and provide fire resistance of up to six hours, depending on their thickness and up to 1,200 degrees Celsius. Therefore, it has also significant fire safety implications.

Moisture Proof

Moisture can cause significant structural damage. The macro-pores within AAC blocks ensure low water absorption. As a result, they offer better moisture protection.

Request exclusive consultation with Ecofab expert

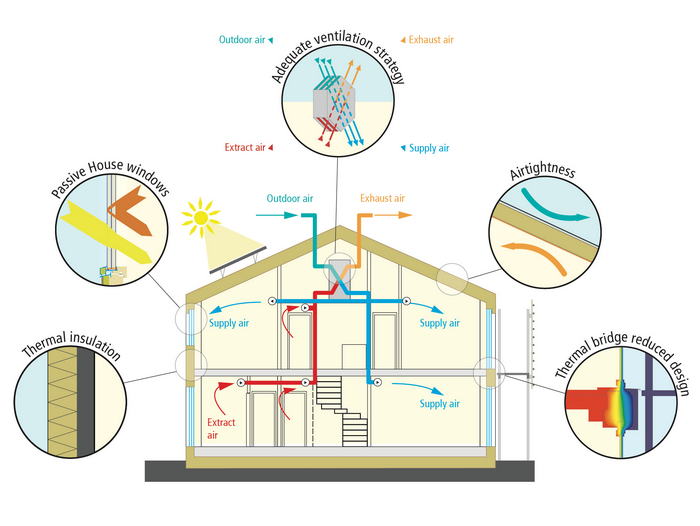

Ecofab building technology 100% meet the Passive House criteria

Request exclusive consultation with Ecofab expert

Easy process to build next generation eco house

Pre-project activities

Project preparation

EcoFab house construction

Move into your house

Request exclusive consultation with Ecofab expert

We can find the perfect plot for you

The house of the future...

we'll build today